April 1996 Volume 2 Issue 6

DEALING WITH POWER QUALITY PROBLEMS

With the increasing use of solid-state electronics, two aspects of electrical power quality concern many production managers:

· Harmonic Distortion: Solid-state motor controllers, thyristor process controllers, switching-mode power supplies (the type used in computers), arc welders, and gas-discharge lighting systems (fluorescent and HID) are essential parts of many production systems. Unfortunately, they all produce pulse-type currents that can produce negative effects, including harmonic distortion of the supply voltage.

· Voltage Transients: Lightning strikes and various other events in the utility distribution system sometimes create high-voltage spikes on low-voltage power circuits.

THE HARMONIC PROBLEM

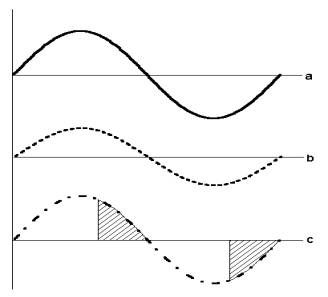

The voltage produced by an electric generator is a smooth constant-amplitude sine wave like that pictured in Figure 1a. And when that voltage is used to drive resistive loads or motors, the current wave is also a smooth constant-amplitude sine wave. The old way to reduce the brightness of a bulb or the temperature of a heating element was simply to reduce the voltage (Figure 1b). The amplitude of the voltage was reduced, but its waveform remained the same. The new way to accomplish these same results is to leave the voltage at its original value, but abruptly switch the voltage on and off at appropriate points in the waveform cycle (Figure 1c). This is done electronically, using solid-state devices known as silicon controlled rectifiers (SCRs) or thyristors.

This rapid switching creates a grossly distorted current waveform that tends to drag down the supply voltage during parts of the cycle, thereby creating harmonic distortion of the voltage wave shape.

Figure 1 — Utility-generated 60 Hertz power begins as smooth sine waves but can be distorted by equipment that uses switching-type power semiconductors.

With a perfect sine wave, all the energy occurs at the fundamental power line frequency of 60 Hz (Hertz, or cycles per second). With a distorted waveform, however, some of the energy appears at multiples of the power line frequency such as 120, 180, 300, 420, 540, 660 Hz — or even higher. These harmonic voltages and currents can cause problems.

Excess heating of iron-core devices

Even when supplied by a perfect sine wave voltage, the magnetic cores of transformers, motors, and lighting ballasts convert some electrical energy into heat within the core itself. When the supply voltage has high harmonic content, this heating effect increases. Thus, harmonics can contribute to the failure of motors, transformers, and similar devices if the devices are operating at or near their maximum ratings.

Heating and failure of power factor correction capacitors

A more serious, more complex problem concerns the capacitors used to correct a low power factor. The current flowing through a capacitor is proportional to the frequency of the applied voltage. Thus, harmonics can cause large high-frequency currents to flow — larger at times than even the fundamental (60 Hz) current. In turn, these large harmonic currents may cause capacitors to get excessively hot and fail.

Excessive current in the three-phase neutral conductor

Most production operations use three-phase power, and within these plants single phase loads are usually connected between individual phases and the neutral wire. A single neutral has traditionally been all that was needed because the fundamental (60 Hz) currents from the three individual phases tend to cancel each other out in the neutral. Harmonic currents, however, can add in the neutral rather than cancel, and in some cases this results in excessive current flow. (The usual solutions are to install a heavier neutral wire, or to install a separate neutral for each phase.)

If you suspect harmonic problems, we at the Energy and Minerals Section (or your electrical utility) can bring metering equipment to your facility and record harmonic current and voltage levels. It is especially important to do this before purchasing and installing power factor correction capacitors. If the line voltage harmonic level is too high, additional tests and special precautions may be necessary.

VOLTAGE TRANSIENTS

Voltage transients are abrupt, short-duration, increases or decreases in voltage. They have a variety of sources:

· lightning,

· utility power switching,

· transient faults in the utility distribution system,

· other utility customers adding or shedding loads, and

· the cycling on and off of high-demand equipment (such as motors or heaters) within one’s own plant.

The type of voltage transients posing the greatest risk of equipment failure are the sudden increases usually referred to as voltage surges or spikes. These can be thousands of volts in amplitude, though of short duration (microseconds or milliseconds). While these voltage spikes do not contain much energy, the extreme voltage can destroy SCRs, thyristors, diodes, and other power semiconductors.

One solution to the voltage spike problem is to install surge suppressors at the power outlets which feed sensitive equipment such as computers and process controllers. With equipment that is connected to both the power system and the telephone system — answering and fax machines, for example — it is important to use a surge suppressor that also protects the equipment from voltage spikes coming in on the phone line. For high power equipment, special heavy-duty surge suppressors are available.

Another way of protecting sensitive equipment from spikes also solves the problem of data and program loss during short-term power failures. It is the uninterruptable power supply or UPS. These devices convert utility AC power to DC battery power and back again to AC. In addition to providing power during power outages, most UPS models also keep voltage spikes, dips, sags, and swells from reaching the equipment.

Power sags are voltage drops that occur when heavy loads are turned on within the facility. Voltage sag problems can sometimes be solved by shifting the heaviest loads to other circuits. A second approach is to install a separate circuit for the sensitive equipment affected by the sag. A third approach, as mentioned above, is to employ a UPS.

CALL US

We at the Energy and Minerals Section would be happy to discuss power quality issues with you. Call Mike Proud or Ron Estabrooks at 368-5010 (toll free).