April 1996 Volume 2 Issue 7

SICK REFRIGERATION SYSTEMS

P.E.I.’s food processing plants depend on reliable, efficient refrigeration for product cooling, freezing, and storage. Unfortunately, the energy-efficiency of these systems tends to degrade over time and, when this happens, electricity bills escalate. If performance slips too far, it can also cause product quality and production efficiency to deteriorate.

Just as an ailing person will have symptoms, so will an ailing refrigeration system. Here we present a checklist of major symptoms, and tell you what sort of underlying problems they may indicate. In some cases you will need help from a refrigeration technician to pinpoint the diagnosis and treat the patient, but corrective action begins with recognizing that a problem exists.

REFRIGERATION SYSTEM WARNING SIGNALS:

1. Compressor runs for unusually long periods of time

In most refrigeration systems the compressor does not run continuously, but cycles on and off. If the system is operating properly, compressor run time will be determined by the refrigeration load. If a large quantity of warm or room temperature product has just been put into the refrigerated space — product in the process of being cooled or frozen — the compressor is likely to run most of the time until the cooling or freezing has been accomplished. Sometimes, however, compressors run for abnormally long periods (or even continuously) for reasons totally unconnected with product cooling or freezing loads. These other reasons include:

· outside heat getting into the refrigerated space (door open too much of the time, door-seal deterioration, or problems with cold-room wall and ceiling insulation),

· dirty condenser, or

· low refrigerant charge.

If you sense that a particular refrigeration compressor runs for longer periods than it used to run, have the system checked out.

2. Temperature of the refrigerated space has changed

Every refrigerated space should have a thermometer that accurately indicates space temperature. A change in that temperature most likely indicates a change in thermostatic control calibration. If, however, the temperature has risen and the compressor runs all the time, it could indicate the sort of problems mentioned above.

3. Sight glass shows bubbles, or is only partially full

Most industrial refrigeration systems have a sight glass located in the refrigerant line between the condenser and the thermostatic expansion valve. If bubbles are visible in the glass after the compressor has been running for 15 minutes or so, it may indicate that the condenser is not cooling the refrigerant sufficiently to change it all back to liquid. Perhaps the condenser is dirty, the condenser fan is not working properly, or the ambient air is excessively hot. Bubbles in the sight glass can also indicate that some of the system’s refrigerant charge has leaked away, leaving the system with a reduced charge.

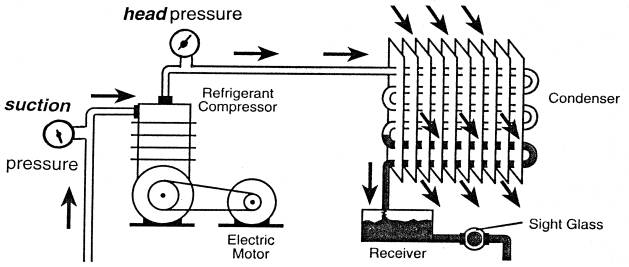

4. Compressor output (head) pressure is abnormally high

Some systems have pressure gauges installed in the compressor input and output lines. They can reveal a lot about system operation. Higher than normal head pressure, for instance, indicates one of several problems:

· The condenser is not getting rid of enough heat. (Common causes are insufficient air flow through the condenser due to dirt or fan problems, or ambient air temperature that is too high.)

· The evaporator is functioning poorly. (Fan failure? Dirt buildup? Defrost system failure?)

· The system has an excessive refrigerant charge.

5. Compressor output (head) pressure is abnormally low

Low head pressure could indicate a condenser that is too cool — perhaps because the temperature of the air blowing through the condenser is abnormally low. It could also indicate low refrigerant charge.

6. Compressor input (suction) pressure is abnormally low

Low compressor input pressure could indicate

· insufficient air flow through the evaporator due to frost buildup on the evaporator coils, a dirty evaporator, product blocking the air flow, or possibly evaporator fan problems,

· expansion valve problems, or

· if low input pressure occurs together with low output pressure, a low refrigerant charge. (This, in turn, suggests a refrigerant leak.)

7. Excessive frost on the evaporator coils

Blocked evaporator air flow will cause this. (Ensure that product is not interfering with air flow.) Other possible causes include:

· Failure of the evaporator fan to function properly

· A dirty evaporator coil

· Defrost system problems

8. Compressor motor current is excessive

Routine checks of compressor motor current and voltage can also reveal problems. Motor current at or near the motor’s full load amps (FLA) rating usually means that the load on the motor is excessive. To find out why, begin by checking compressor input and output pressures.

FREE REFRIGERATION BOOKLET AVAILABLE

Energy Efficient Refrigeration Systems is a 28-page booklet that discusses how refrigeration systems work, and how to cut the cost of running the refrigeration systems that are part of your business. If you’d like a copy, phone Mike Proud or Ron Estabrooks at 368-5010 (toll free).